Brand CasesNew Balance Reduces Environmental Impacts across the Value Chain

Publication Date:2022-08-29

View:6037

The environmental impact of facilities, operations and supply chains are well-recognized by New Balance.

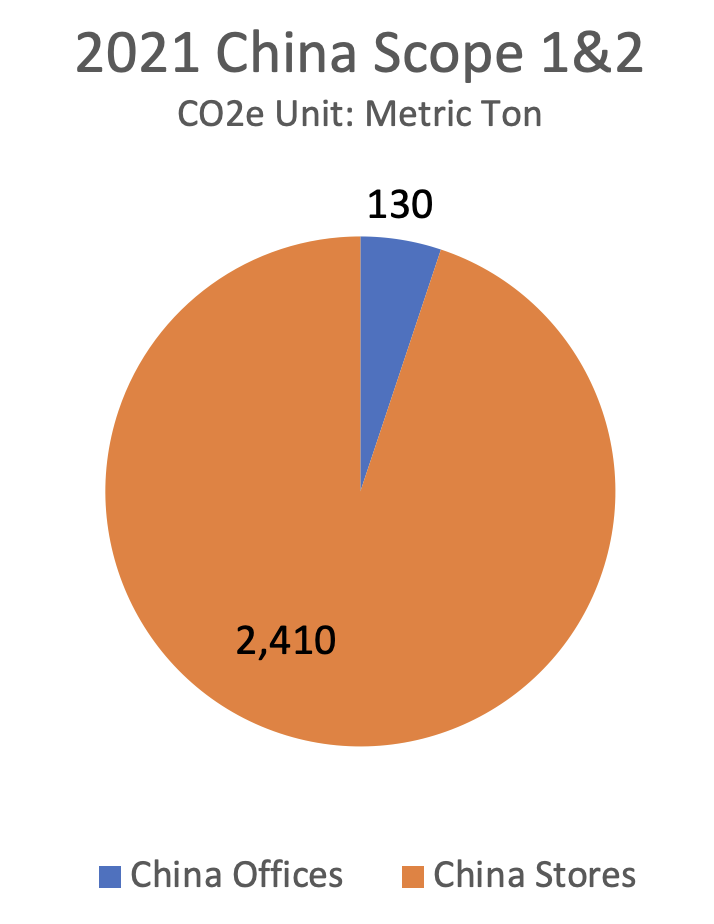

In China, New Balance’s Scope 1 & 2 carbon emissions are primarily generated from purchased electricity for 102 operated stores and 4 offices (click to see the data). Total Scope 1 and 2 emissions in 2021 were 2,540 MTCO2e, with 95% of that associated with retail stores. New Balance does not always have visibility to energy consumption and billing for all sites, so a large part of this retail data is estimated based on store floor area and average energy use per area for typical retail space.

As a member of RE100, New Balance has committed to achieving 100% renewable electricity across all global owned/operated sites by 2025, including these stores and offices. As of 2021, 58% of New Balance's global electricity is sourced as renewable. New Balance has also signed on to the Business Ambition for 1.5⁰C and is currently submitting a 1.5⁰C-aligned Science Based Target (SBT) for approval. This SBT will also address Scope 3 emissions, which is largely driven by purchased goods and services (Category 1). Two of the most important Scope 3 reduction pathways are maximizing resource efficiency and switching to renewable energy across the supply chain.

Since 2015, New Balance has participated in the Clean By Design (CbD) program to reduce their footprint as the climate change crisis and water risk continues.

Over the course of their CbD engagement, New Balance has sponsored seven strategic mills located in China and to engage in the CbD program. Each mill engagement focused on energy and water efficiency with expert interventions and advice spanning one to two years per site.

New Balance has seen significant improvements in resource efficiency at mills that have completed the program. The figures below show the carbon and water savings that five of the mills were able to achieve though the program – over 6,500 MTCO2e and 1.3 million cubic meters of water. Top opportunities for improvement included: recycling condensate water, insulating steam pipelines and valves, properly maintaining steam traps and valves, upgrading air compressor systems, utilizing waste heat and optimizing dewater measures.

In 2021, New Balance cooperated with the Apparel Impact Institute (Aii) to develop a CbD New Construction program using one strategic supplier that was building a new mill as a pilot for program development. So far, 14 recommendations have been applied during the mill’s design and construction phases. This effort is still on-going and New Balance expects to see more positive outcomes.

(The above content is provided by the relevant brands, and the authenticity of the data is the responsibility of the brand)