Panasonic's business in China has

always been oriented towards sustainable development since the very beginning. In product design, manufacturing and recycling, Panasonic is committed to using advanced technology to protect our planet and

contribute to greening

lives.

Environmental management systems

To

support the implementation of the environmental management PDCA

(Plan-Do-Check-Action) cycle, Panasonic established an environmental

performance system called "EcoSystem

(Factory)" that

collects and manages environmental data for all manufacturing plants on a

global scale. Every factory regularly reports data on energy use, water use,

waste, production value, and chemical release and transfer. Based on this set of environmental big data, the Group, companies in the business as well as

local environmental departments can clearly understand the progress of the manufacturing plants' environmental management activities, identify problems, and implement solutions to further promote environmental activities.

Since

2016, Panasonic has started to publish pollutant emissions and transfer (PRTR) data for its

Chinese subsidiaries, covering PRTR data promoted by the Institute of Public & Environmental

Affairs. In 2017, the number of featured subsidiaries expanded from 10 in 2016

to 14 sites, of which seven were included for two consecutive years

(based on Japan's fiscal year, from April 1stof a

given year to March 31stof the following year).

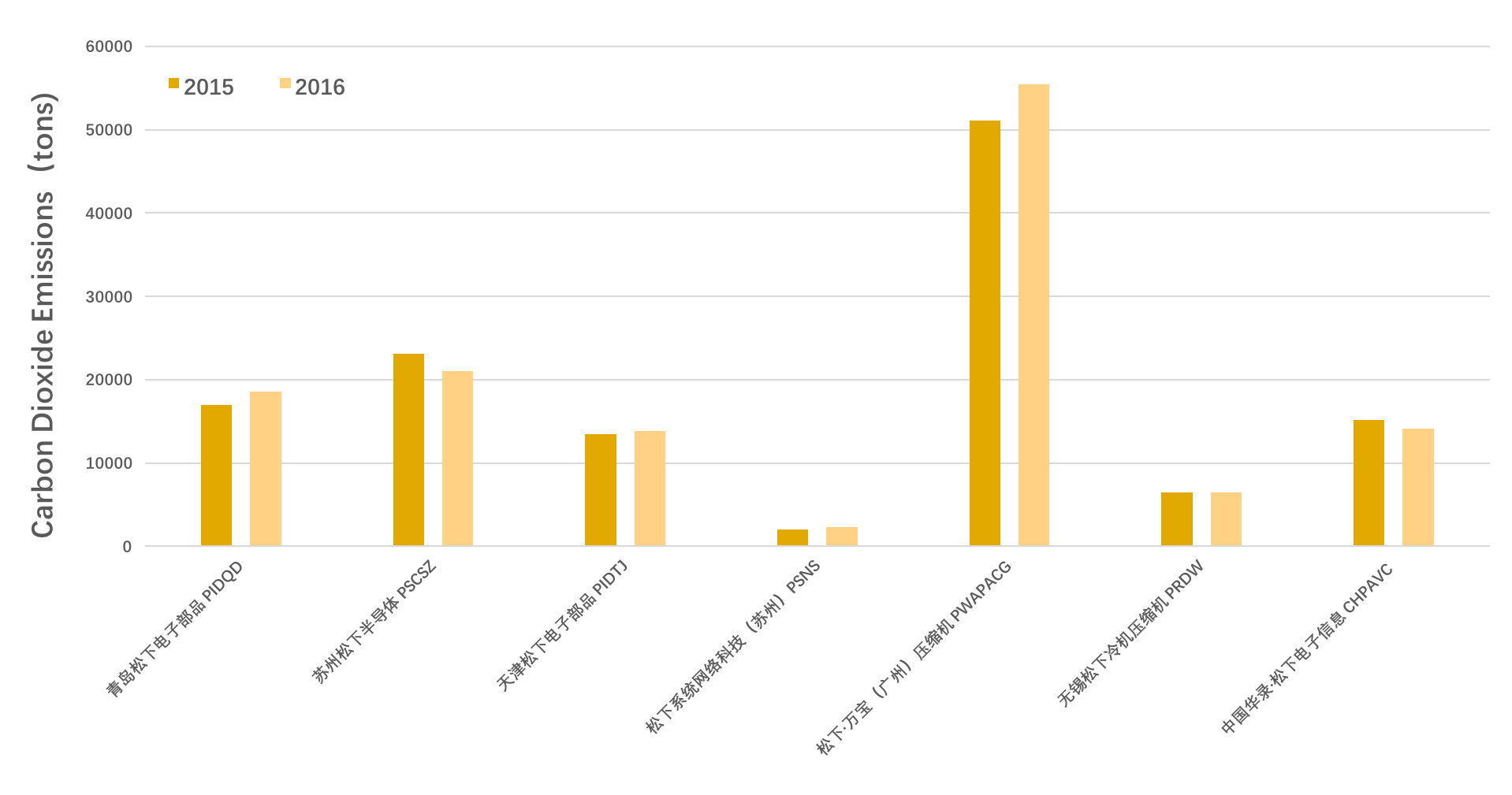

Reduction of carbon dioxide in production activities

Panasonic

reduces its impact on the environment by continuously improving its energy efficiency

systems and cutting down carbon dioxide emissions per unit of

output. In addition to carbon dioxide, Panasonic plants have adopted further

measures in their production processes, such as implementation of gas

replacement, installation of treatment equipment, treatment of fluorine gas and

other measures to actively reduce perfluorocarbons, sulfur hexafluoride and

other major greenhouse gas emissions. The carbon dioxide emissions of the seven

subsidiaries of Panasonic China featured in both 2015 and 2016 are as follows:

Among these subsidiaries, Panasonic Wanbao (Guangzhou) Compressor Co., Ltd. adopted

greenhouse gas reduction measures that include the following:

1) Solar power generation: Installation of a 2207 kW

solar photovoltaic power generation system on the factory’s rooftop. In October

2014, the system started generating power to the municipal power grid, producing

2.05 million kWh of energy and saving 1517 tons of carbon dioxide per

year.

2) Motor energy-saving: A comprehensive investigation

and elimination of 319 outdated motor units, corresponding

to 1,213kW,

leading to an

annual reduction of carbon dioxide emissions by more than 700 tons.

3)

Transformation of the plant: Intensification,

rectification and automatization procedures to create high-efficiency,

high-yield workshops. Once the project is completed, carbon dioxide emissions will

fall by 3682 tons compared to 2015 levels. The energy consumption of a single

compressor will fall by 9.9% compared to 2015.

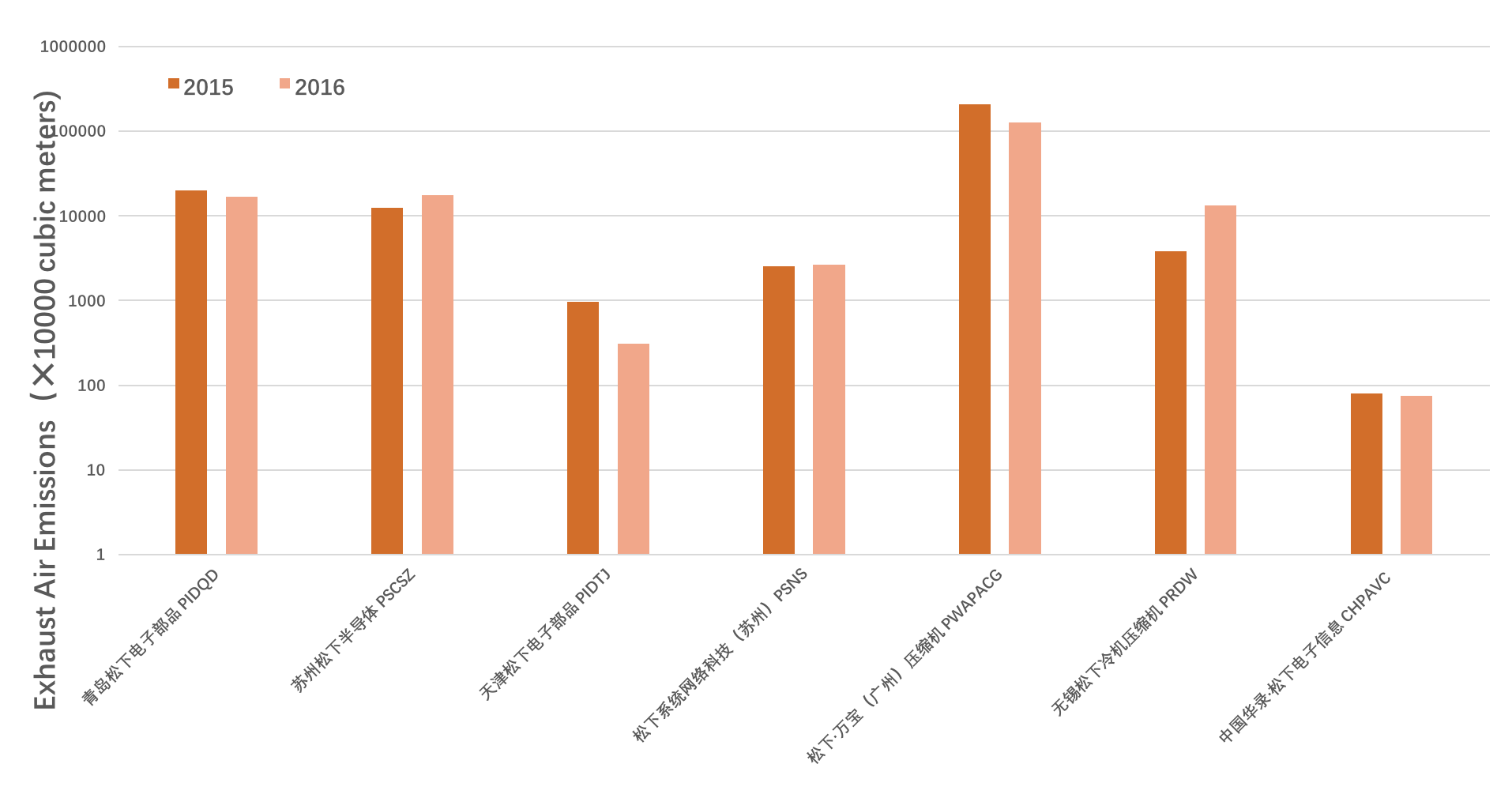

Process

waste reduction

In its "13th Five-Year Plan on Environmental Protection," the Chinese government put forth expected binding targets and plans to implement

special governance measures. The

Plan also comprehensively promotes emissions

reduction and pollution abatement. Panasonic China positively responded to

these calls, strengthening its support for pollutant reduction work. The process waste emissions of the seven subsidiaries

of Panasonic China featured in both 2015 and 2016 amount to the following:

For example, Panasonic Wanbao Appliances Compressor

(Guangzhou) Co., Ltd. increased the number of its gas emissions facilities by

11 starting from 2015, reducing VOC (volatile organic compound) emissions by 29

tons per year.

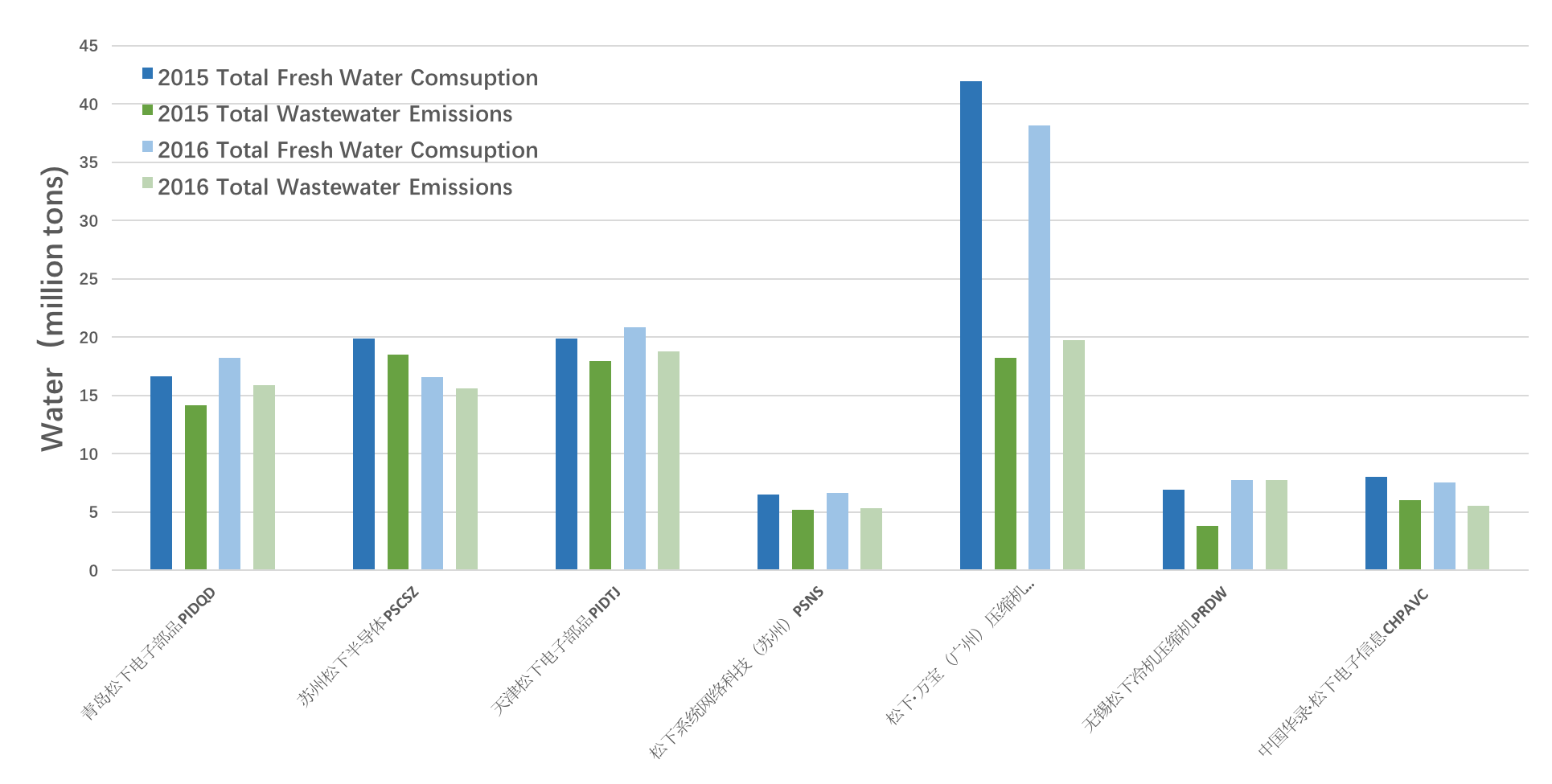

Water resources protection

Indicators show that water

consumption per unit of output have fallen in Panasonic China plants.

Furthermore, Panasonic has adopted other measures to increase recycling

efforts, such as prohibiting direct release of water from air conditioners and

promoting water consumption reduction. Water use and wastewater discharge by

Panasonic China plants between 2014 and 2016 was as follows:

(The above content was provided to IPE by the brand, who is responsible for the accuracy of the data.)